Inverter Efficiency Calculation and Equation Guide

An inverter’s efficiency refers to the amount of AC output power it provides for a given DC input. This is typically between 85 and 95 percent, with 90 percent being the average. When it comes to running things like motors, efficiency is divided into two categories: inverter efficiency and waveform efficiency.

Most motors and many electrical appliances run more efficiently and consume less power when powered by a sine wave. When powering an electric motor, a modified sine wave will frequently require 15% to 20% more power than a real sine wave (such as a pump or refrigerator).

When selecting an efficiency-based power inverter, it is critical to consider the type of loads being powered in order to evaluate true system efficiency.

What Does Efficiency of Inverter Mean?

The efficiency of a power inverter refers to how much of the power that enters it is converted into usable AC (nothing is ever 100 percent efficient, there will always be some losses in the system). This efficiency figure varies depending on how much power is being used at the time, with more power resulting in higher efficiency.

When only a small amount of electricity is consumed, efficiency can range from slightly more than 50% to well over 90% when the output is close to the rated output of the inverter. Even if you aren’t using it for AC power, an ac inverter will consume some of the power from your batteries. As a result of this, low efficiency occurs at low power levels.

Types of Losses

The efficiency of an inverter refers to how much DC power is converted to AC power, as some power is lost during this transition in one of two ways:

- Standby power is only used to keep the inverter powered on. It is also referred to as inverter power usage when no load is present.

As a result, the inverter’s efficiency equals Pac/Pdc, where Pac represents ac output power in watts and Pdc represents dc input power in watts.

The normal efficiency of high-quality pure sine wave inverters ranged from 90% to 95%, while the typical efficiency of low-quality modified sine wave inverters ranged from 75% to 85%.

This power inverter efficiency result varies with inverter load power capacity, as efficiency rises and may reach its maximum value at higher load power capacity compared to lower load power capacity, provided the inverter output power capacity limit is not exceeded.

In general, if the inverter is only partially loaded, the efficiency will be low. As a result, a good match between inverter capacity and load capacity will allow us to achieve greater efficiency, or more AC output power from the inverter for the same DC input power.

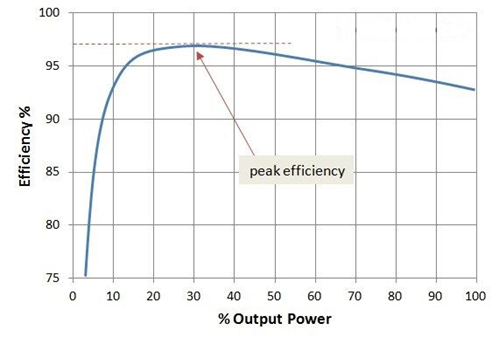

Inverter Efficiency as a Percentage of Output Power (Reference: inverter.com)

A 3Kw inverter will typically draw about 20 watts from your batteries when no AC is present. As a result, if you use 20 watts of AC power, the power inverter will draw 40 watts from the batteries, yielding a 50% efficiency.

A modest 200W inverter, on the other hand, may use only 25 watts from the battery to produce a 20-watt AC output, yielding an 80 percent efficiency.

A bigger power inverter will typically include a feature called “Sleep Mode” to improve overall efficiency. If AC power is required, a sensor within the inverter detects it. If it does not, the inverter will be turned off, but it will continue to detect whether or not electricity is required. In general, this can be changed so that simply turning on a small light is enough to “turn on the inverter.”

Of course, this means that appliances cannot be left in “stand-by” mode, and some appliances with timers (such as washing machines) will not be able to drain enough power to keep the inverter “on” unless something else, such as a light, is turned on at the same time.

Important considerations include wave shape and inductive loads (i.e. a device where an electrical coil is involved, which will include anything with a motor).

Any waveform that is not a true sine wave (i.e. a square or modified square wave) will be less efficient when powering inductive loads – the device may use 20% more power than if a pure sine wave is used. This increased power demand, in addition to lowering efficiency, may harm or shorten the device’s life due to overheating.

Efficiency of Inverter Types

There are three types of inverter efficiency, and we need to understand what they mean and how they differ in order to better understand the numerous inverter datasheet models and manufacturers on the market:

- EU weighted efficiency

ηEU=0.03η5+0.06η10+0.13η20+0.10η30+0.48η50+0.20η100

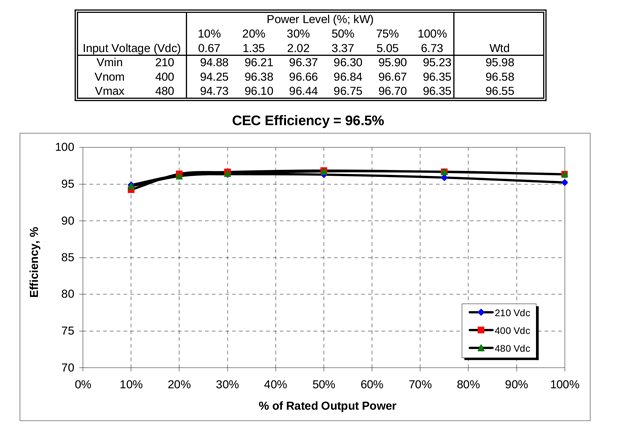

- Cec Weighted Efficiency

ηCEC =0.04η10+0.05η20+0.12η30+0.21η50+0.53η75+0.05η100

Peak efficiency refers to the maximum efficiency of an inverter that can be achieved at ideal output alternating current power, and it can only be used as a quality indicator for inverters.

European efficiency: It is calculated by measuring inverter efficiency at various AC output power points and multiplying it by various weighted numbers. It’s more important than peak efficiency because it shows how the inverter performs at different output power levels during the solar day.

California energy commission efficiency: It relates to inverter efficiency evaluated at different ac output power points, then multiplied by different weighted values; thus, it is similar to European efficiency, but it employs different multiplied weighted numbers (different calculation formula).

The fundamental difference between European and California efficiencies is the importance of each AC output power level when evaluating efficiency for a given inverter.

Efficiency of Inverter Curves

The efficiency of an inverter, which determines how much of the DC power generated by a solar array is converted to AC power, is not always a fixed number. This parameter, on the other hand, varies with the input DC power and voltage, with the degree of variation being specific to the ac inverter.

The California Energy Commission (CEC) monitors testing results on various inverters, expressing efficiency as a function of DC power at three different voltages within each inverter’s operating voltage window. As an illustration, the CEC data for a string inverter is shown below.

Inverter Curve Efficiency Using the CEC Method (Reference: help.aurorasolar.com)

Instead of calculating DC/AC conversion losses using a fixed, weighted efficiency, the performance simulations can examine the entire efficiency of the inverter curve for devices with CEC test data. They fit a parabolic curve to data from power- and voltage-dependent efficiency using a model developed by Sandia National Laboratories. An efficiency curve from Aurora’s component database, which provides CEC data, will be used in the simulation by an inverter.

If a database inverter is unable to simulate an efficiency curve due to a lack of CEC data, the simulation will use a fixed efficiency curve (the smallest of the CEC, European, and maximum efficiencies from the datasheet). Custom inverters will also simulate the lowest fixed efficiency rating from the datasheet.

If an efficiency curve model was used, a log note will be included in the performance simulation report indicating which fixed efficiency was used if the efficiency curve was not available. If no efficiency statistics are available for the component, an error will be generated.

On inverters with multiple MPPTs, each maximum power point tracker (MPPT) operates at its own efficiency. In the same inverter, an MPPT with shorter strings or less input power may be less efficient than another MPPT with higher input voltage and/or power.

Impact on Energy Production

The inverter’s efficiency decreases when the DC input power is low in comparison to the nameplate rating. As a result, keep the following in mind:

Undersized designs (in terms of input voltage, but especially in terms of input power) for the chosen inverter will have a lower overall DC/AC conversion efficiency than those that are appropriately designed. String sizing validation can help you ensure that your designs are compatible with the inverter you’ve selected.

Inverter efficiency is lower during hours when the array output power is low, such as due to shading or being extremely early/late in the day, than during hours when the array is running under full irradiance with no shading. This is normal behavior, but because the input power is low, it usually has no effect on system performance.